| |

3°/ Spacing between rollers

The following table shows approximate spacing between LIMBEROLLER®, depending on the width of the belt and the density of the products being transported.

In the case where the products transported are particularly fine or, on the contrary, are in the form of large blocks, the indicated spacings may be increased or decreased:

NOTE : The size of the blocks must not exceed one third of the width of the belt.

APPROXIMATE SPACES BETWEEN LIMBEROLLER®

(May vary slightly depending on load and speed) |

| Belt dimensions |

Density of products transported |

| 0,8 à 1,4 |

1,4 à 2,5 |

2,5 à 3,2 |

500

650

800 |

1,80 m

1,80 m

1,80 m |

1,50 m

1,50 m

1,50 m

|

1,30 m

1,30 m

1,30 m |

1 000

1 200

1 400 |

1,80 m

1,70 m

1,50 m |

1,50 m

1,30 m

1,20 m |

1,20 m

1,10 m

1,00 m |

In the case of heavily loaded conveyors it may be necessary to reduce this gap to achieve an acceptable life span of the LIMBEROLLER® roller bearings. It is also possible to relieve these bearings, keep the same flow 4 m / s which is a maximum for our rollers. In extreme cases act on both parameters at once.

The distance between the LIMBEROLLER® can be influenced by the stiffness of the belt, especially when using a very soft belt. It is recommended that the user contact the tape supplier to determine the maximum spacing between the rollers, taking into account the trough angle used (see paragraph 4).

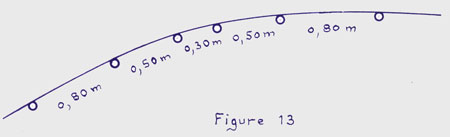

Changing Slopes

When an inclined conveyor is moved horizontally, the number of LIMBEROLLER® rollers must be increased substantially to the slope chan- ging point as shown in the diagram below.

|

|